In the oilfield the mud gas separator is sometimes known as poor boy degasser or gas buster. They may be vertical or horizontal in design.

Mud Gas Separator Poor Boy Degasser Stock Vector Royalty Free 214060696

Its type are vertical type only.

. Firstly vacuum degasser structure design is more complex than poor boy degasser. There are two generic types that work by both expanding the size of the gas bubbles entrained in the mud by pulling a vacuum on the mud and by increasing the surface area available to the mud so that bubbles escape through the. These separators are frequently home-made and may be inadequate for handling large kicks.

Mud gas separator is commonly called a gas-buster or poor boy degasser. They use the poor boy degasser in 800bbl total treating capacity system. The volumetric flow capacity of the system should be based on an adequate gravitational rate from the separator.

It captures and separates large volume of free gas within the drilling mud. Drilling Mud Gas Separation 320m3H Poor Boy Degasser. The vacuum degasser is composed by tank motor system electronic control system and so on.

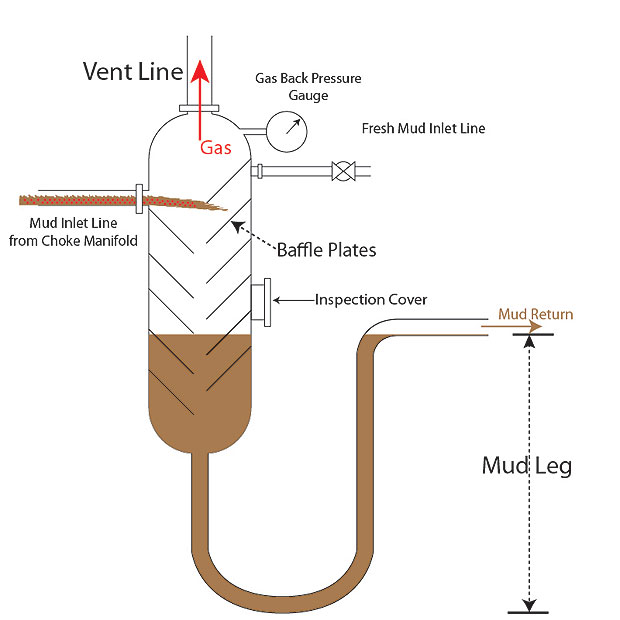

The mud from the drilling well goes into the poor boy degasser as showed in the blue. FLQ Poor boy degasser is one kind of drilling fluid equipment. Connection is between chock manifold and degasser inlet line.

A mudgas separator poor boy degasser sizing worksheet will assist drilling personnel with the sizing calculations. This Thailand customer is an oilwell drilling services company they has special requirements on the poor boy degasser. Oilfield poor boy degasser introduction.

The poor boy degasser usually used in deep oilwell drilling it is also named as Mud gas separator. At presentDC Solid control finished the production of ZYQ1200 Mud gas. The separators are used primarily to separate and reliably vent large pockets of free gas from the active mud system.

This points out the importance for providing a large diameter gas. High efficiency and easy to maintain Large capacity Easy transportation and installation. They may be vertical or horizontal in design.

A Vertical separator is normally used for high fluid throughput while a horizontal separator provides a longer retention time and superior gas separating capacity. The gas then is forced to flow through a line venting. For oil drilling poor boy degasser is the first equipment to process drilling fluid.

High mud flow treating capacity flexible installation and ideal dimension design for oversea and land transport. Poor boy degasser is the kick off equipment used in oil and gas drilling site. It mainly get rid of invaded gas and remove large pocket of gas to keep well drilling and rig safe.

What is Mud Gas Separator. If there is a kick situation this vessel separates the mud and the gas by allowing it to flow over baffle plates. It is usually painted in red color as a warning at oilfield.

They requested the vessel diameter should be 36. A typical liquid capacity of 6 barrels per minute of 12 pounds per gallons drilling fluid of average viscosity is a guide for vertical mud gas separator. If there is a KICK situation this vessel separates the mud and the gas by allowing it to flow over baffle plates.

Mud Gas Separator is commonly called a gas-buster or poor boy degasser. The mud gas separator vent line is connected to the flare ignitor. The gas then is forced to flow through a line and.

Mud gas separators in other countries also called Poor boy degasserLiquid-gas separators MudGas Separators etc. Assuming a 98 ppg mud and total U-tube height of 10 ft the fluid seal would have a hydrostatic pressure equal to 5096 psi. Poor boy degasser also referred to mud gas separator is an ideal equipment to operate when drilling is likely to encounter large volumes of gas.

It captures and separates the large volumes of free gas within the drilling fluid. The main parts are degasser vessel degasser support or pedestal lay down leg mud feed inlet discharge output ventline drain discharge also. The worksheet provides a quick and easy evaluation of most mudgas separators for a specific well application.

As we said mudgas separators and degassers mechanically remove entrained gases such as hydrogen sulfide carbon dioxide and natural gas from the mud system. Large quantity gas will be separated out swiftly. The mud outlet downstream of the U-tube should be designed to maintain a minimum vessel fluid level of approximately 3 12 ft in a 16 ft high separator.

Poor Boy Degasser Design Drawing There is the Birghway design drawing of poor boy degasser. In the oilfield the mud gas separator is sometimes known as poor boy degasser or gas buster. This fluid passes through the choke manifold and is processed through a separate tank called a mudgas separator or gas buster or poor-boy degasser Fig.

Oilfield drilling Poor boy degasser that removes air or gases methane H2S CO2 and others from drilling liquids. Poor boy degasser Liquid Throughputs. These poor boy degasser are equipped with distinct inlet air temperature and outlet air temperature with centrifugal atomization drying methods for enhanced performance.

Mud gas separator combined with throttle manifold together to separate the free gas within drilling mud. This paper discusses design considerations for mudgas separators poor boy degasserThe purpose of this paper is to allow drilling rig supervisors to evaluate mudgas separators properly and to upgrade if required the separator economically to meet the design criteria outlined in this paper and to provide office drilling personnel with guidelines for. Mud Gas Separator Poor Boy Degasser provided by CCSC Technology is designed to capture and separate large volume of free gases within the drilling fluid.

Heavy anticorrosive painting 3 layers zinc rich epoxy painting for bottom and mediate layers and PU painting for top layer. ZYQ series Mud gas separator Poor Boy Degasser is professional equipment to treat the gas invade mud. From the design drawing of poor boy degasser we can know there are four colors of arrows in the drawing which present mud gas liquid of mud and mud deposit.

Poor boy degasser in oil drilling. The best part of buying these efficient poor boy degasser is the after-sales service that involves maintenance and other associated activities. Poor Boy Degasser Features.

A Vertical separator is normally used for high fluid throughput while a horizontal separator provides a longer retention time and superior gas separating capacity. It is designed for high pressure wells this unit controls the circulated gas to the surface separating the gas from the mud and release it. Mud gas separator located at downstream of the choke manifold is one of the important well control equipment that you need to focus.

Will be designed internal block blade certain height mud sealleg. H2S resistant material for degasser body. When the drilling mud result gas invade the proportion of its weight and viscosity have a greater deviation not to meet the requirements of drilling.

The degasser is connected with the choke manifold and the discharge line connected with the shaker inlet or the flow divider. Poor boy degasser design Poor boy degasser is called mud gas separator also. Poor boy degasser is also referred to mud gas separator liquid gas separator or gas buster.

Usually it is set ahead of shaker but connected. Bottom Sealing 240m3H API Standard Oilfield Separator.

What S A Poor Boy Degasser Mud Gas Separator

Design Of Specifications Of Poor Boy Degasser

What S A Poor Boy Degasser Mud Gas Separator

Oilfield Drilling Poor Boy Degasser Mud Solids Control Equipment

The Evaluation And Sizing Of Mud Gas Separator Drilling Fluid Management Disposal

Poor Boy Degasser Customized Design For Thailand Client Gn Solids Control

0 comments

Post a Comment